Met Lab

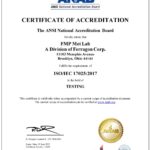

FMP Met Lab is a full service metallurgical testing laboratory that plays an integral role in FMP’s ability to deliver high quality, on spec material to customers. Accredited to ISO/IEC 17025:2017, FMP Met Lab’s on-staff metallurgists assure that you get accurate, dependable metallurgical testing results and that your delivered material has the properties important to your customers.

Lab Capabilities

Our lab has a full complement of equipment to consistently and accurately perform the following Commercial Lab mechanical testing services for metal sheet, strip and plate:

- Tensile Testing

- Rockwell Hardness Testing

- N-Value (Strain Hardening Exponent)

- Superficial Hardness Testing

- Bend Testing

- Metallographic Analysis

- Grain Size

- Inclusion Content

- Depth of Decarburization

- Degree of Spheroidization

- Photomicrography